We are having our own Investment casting foundary setup so every process are done under one roof. We believe that wax patter quality is mirror of finish casting quality. Normally we use Pattern wax, and soluble wax for Accurate Pattern Making. In Netflow we have semi Automatic Wax Injection Press with Vertical injection, fully automatic wax injection press with vertical & horizontal injection and Runner bar extrusion press and Because of this Fully pattern inspection ensures most preciseness in castings.

we are using fused silica, Zircon sand, colloidal silica (water based) binder for different applications. We have temperature Controlled and humidity controlled Drying room with Dehumidifiers.

Our melting department is equipped with Electrotherm make induction furnace with 25 Kgs , 150 Kgs and 300 kgs crucibles and temperature controlled Shell Baking furnace. We are using standard and best quality scrape to ensure best metallurgy of Valves casting products.

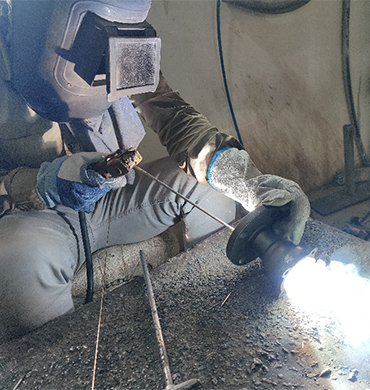

Our fettling department is equipped with Machines for Shot Blasting, Abrasive cutting , Belt grinding, Welding and other machinery. We have temperature Controlled and humidity controlled Drying room with Dehumidifiers.

Heat treatments are used to control hardness, mechanical properties, corrosion resistance and surface treatments. Heat treatment processes are being done as per customer requirements.<br> We are using standard and best quality scrape to ensure best metallurgy of casting products.

our latest machining room have the ability the worked out material is sheared away gradually and the end result is a perfectly finished intricate part of Valves or final Valves product. We have very precise machining infrastructure house that makes our products best in class.

Netflow’s responsibility is to ensure that all materials and equipment are properly packed for its intended mode of shipment. Machined surfaces are protected with requisite protectors and sealed against corrosion. Sensitive instruments, especially electronics, are removed and packed separately if required. Packing is performed in compliance with established and approved Packing Procedures, and in compliance with Customer Requirements, if so required.